Powder Injection Moulding – A revolution in precision metal and ceramic components production

Powder Injection Moulding (PIM), comprising Metal Injection Moulding (MIM) and Ceramic Injection Moulding (CIM), is an advanced manufacturing technology for the production of complex, high volume net-shape components.

Visualmax PIM Division is a leading manufacturer of small and precisely engineered metal components. Utilizing proprietary die cast and powder injection moulding technologies, we offer robust solutions to companies in automotive, consumer electronics, healthcare, hardware, computers and peripherals and many other industries.

We engineer precision components by combining extensive engineering knowledge with our specialized manufacturing systems. We help companies around the world save money by identifying components and assemblies in their products that can be redesigned or consolidated using one of our manufacturing techniques. We have been delivering value to our customers through our engineering expertise, efficient operations and Advanced Quality Planning systems.

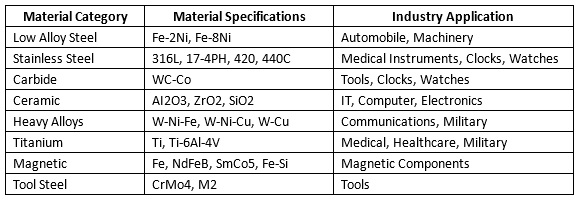

Applicable Materials:

PIM is applicable to wide range of materials which includes low alloy steel, stainless steel, tool steel, nickel-based alloys, tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc.

Table – Typical PIM materials and applications